Sustainability in the cleanroom

A scientific approach

By Stefaan Vanhalle – R&D Manager

The cleanroom industry is at a crossroads, facing increasing demands for sustainability while adhering to strict regulatory requirements.

The European Green Deal (EGD), which outlines the EU’s plan for a climate-neutral economy by 2050, is driving much of the regulatory shift. Key legislative elements such as the Ecodesign for Sustainable Products Regulation (ESPR), the Corporate Sustainability Due Diligence and Reporting Directives (CS3D, CSRD), the Deforestation-Free Products Regulation (EUDR), and the Packaging and Packaging Waste Regulation (PPWR) have already entered into force, laying the foundation for a more sustainable future.

While these regulations are in effect, specific details, such as criteria and exceptions, are still being refined through implementing or delegated acts. These acts play a crucial supporting role by defining technical requirements and ensuring the regulations are effectively applied. For instance, the Digital Product Passport (DPP), a key element of the ESPR, will be further developed via Delegated Acts, with priority given to sectors like textiles, furniture, and car tires. Meanwhile, the European Commission’s Omnibus revisions aim to balance sustainability ambitions with reduced administrative burdens for businesses under the Green Deal framework.

However, the challenge lies in integrating these regulations effectively into cleanroom operations. As the pharmaceutical sector emphasizes environmental responsibility, regulations aim to enhance corporate accountability and transparency. Nevertheless, these sustainability directives often conflict with the industry’s stringent contamination control measures. Annex 1 of the GMP guidelines, for example, mandates energy-intensive air handling systems and strict environmental controls to ensure product safety. While necessary for maintaining aseptic conditions, these measures lead to high energy consumption and material waste.

Additionally, to preserve the sterility of products, suitable and validated packaging is required. However, the Packaging and Packaging Waste Regulation (PPWR) imposes demands for the use of biobased and recyclable materials, creating another layer of complexity in balancing product safety with sustainability efforts. Companies must navigate these contradictions to balance regulatory compliance with meaningful sustainability efforts.

Greenhouse gas emissions and reduction targets

Measuring emissions and setting reduction targets are crucial for effective climate action. Companies are increasingly aligning with frameworks like SBTi to meet global climate targets based on the Paris Agreement’s 1.5°C objective. This requires companies to reduce CO2 emissions and other greenhouse gases (GHGs) within a scientifically grounded framework.

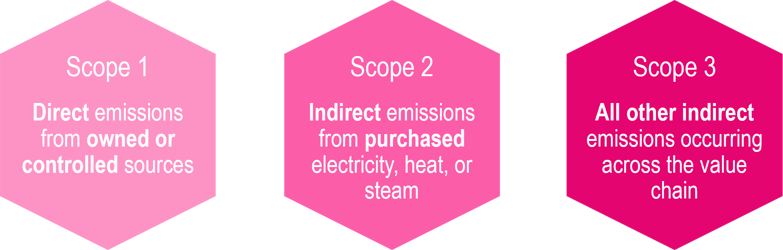

Scope 1, 2, and 3 emissions

Understanding the categorization of emissions is essential for targeted reduction efforts:

|

For cleanroom operations, Scope 3 emissions often represent the largest source of environmental impact yet remain the most challenging to address. While Scope 3 reduction is the most complex category, it can also be the most cost-effective. For instance, negotiating lower-emission supply chains may require little more than adjustments in annual contract discussions or tendering processes, yet it can significantly reduce Scope 3 emissions, often accounting for up to 90% of a company’s total footprint. Companies must develop strategies that extend beyond direct operations to reduce their overall carbon footprint. To tackle this challenge, many organizations turn to Product Carbon Footprint (PCF) assessments for one fundamental reason. By calculating Scope 3 emissions based on actual product carbon footprints rather than spend-based estimates, companies achieve a more accurate and often lower CO2e emission profile. The use of detailed, activity-based data provides a clearer picture of emissions, leading to better-informed procurement decisions and more effective reduction strategies. |

However, reliance on Scope 3 accounting often leads to double counting. What is classified as a Scope 3 downstream emission for suppliers is an upstream emission for customers. This overlap occurs because emissions are assessed across the entire value chain, so companies take responsibility for their indirect impacts. The goal of Scope 3 reporting is not a perfectly additive total, but to ensure that each company understands its role in the value chain’s overall emissions. While a perfect accounting system where all organizations fully track and reduce their Scope 1 and 2 emissions could reduce Scope 3 complexity, it would not eliminate the need for Scope 3 reporting. Value chains remain interdependent, and understanding indirect emissions is essential for driving systemic reductions beyond a company’s direct operations. |

Measuring carbon footprint: LCA and PEF

To assess carbon footprint, Life Cycle Assessment (LCA) and Product Environmental Footprint (PEF) methodologies are commonly used:

|

|

|

However, these methods have limitations. They are time-consuming and costly, while results can be influenced by regional and temporal factors. Additionally, the flexibility in data selection can make objective comparisons difficult, leading to inconsistencies in assessment outcomes. These challenges highlight the inefficacy of a one-size-fits-all approach.

Given the complexities of measurement methodologies, a pragmatic approach to CO2 reduction is essential. Such an approach can also make a company more efficient. Instead of waiting for a perfectly calculated LCA or PEF, organizations should prioritize impactful actions such as:

-

Supplier negotiations to improve scope 3.1 emissions

-

Improving energy and resource efficiency in cleanrooms and in general, as it also saves costs

-

Transitioning to own renewable energy sources and self supply, as the costs for solar energy systems still drops dramatically

-

Optimizing supply chains and logistics, which also reduces your customers' Scope 3 carbon footprint (action-based) and can therefore be a sales argument, especially for big accounts

-

Enhancing circularity. Waste, as long as not contaminated, can be a valuable resource for other companies, especially with growing EPR and recycled content requirements from legislation

LCA and PEF results are also influenced by regional and temporal factors, making a one-size-fits-all strategy ineffective. Companies must adapt their sustainability efforts based on industry-specific challenges.

Sustainability is a shared responsibility, and progress does not require perfection

This principle applies to manufacturers and suppliers as well: rather than waiting for the perfect plan or getting lost in complex calculations, it is often far more effective to take immediate action by implementing broad, high-impact sustainability measures.

Practical strategies such as optimizing packaging by reducing excess air, using recycled materials, and adopting TCF-free boxes, improving transport efficiency, and minimizing material waste can deliver substantial environmental benefits in the short term. These tangible initiatives often have a greater positive impact than investing significant time and resources into calculating precise PEF scores, which primarily serve as theoretical benchmarks.

While measurement and precision play an important role, they should not become barriers to meaningful progress. The focus should be on collective action and real-world improvements, rather than solely on regulatory compliance. By acting now instead of waiting for the perfect solution, we can drive meaningful change, because ultimately, “better” should never stand in the way of “good.”

Moving Beyond Carbon: a holistic sustainability strategy

Sustainability isn’t just about emissions. It also encompasses ethical labor practices, human health, responsible procurement, and corporate responsibility. This is where frameworks like EcoVadis play a crucial role. By evaluating companies across four key sustainability themes, including climate impact, EcoVadis encourages organizations to adopt a broader, more actionable sustainability strategy rather than focusing solely on carbon metrics. The EcoVadis rating methodology measures a company’s sustainability management system based on policies, actions, and results.

Regulatory compliance is the first step toward sustainability, but true impact requires proactive measures. The EcoVadis methodology is based on the ISO 26000 standard, which encourages companies to go beyond mere legal adherence. Organizations must demonstrate active implementation of sustainability initiatives rather than relying on policy declarations alone.

Critics of EcoVadis sometimes claim it operates as a “pay-to-play” model. However, this is a misconception. The assessment fee is determined by objective criteria such as company size and revenue, and EcoVadis does not rely solely on self-reported data. External databases and independent sources ensure a credible, verifiable assessment of sustainability performance.

Conclusion

The cleanroom industry faces a critical challenge: balancing strict regulatory compliance with the growing demand for sustainability. The European Green Deal and related legislation are driving a shift toward greener operations, but achieving meaningful progress requires navigating contradictions between contamination control standards and environmental regulations.

Reducing greenhouse gas emissions is a key priority, with companies increasingly aligning with frameworks like SBTi to meet global climate targets. However, Scope 3 emissions, often the largest and most complex category, present significant measurement and reporting challenges. While methodologies like LCA and PEF provide structured assessment tools, they are not perfect, and overreliance on calculations can slow progress. Instead, a pragmatic approach—focusing on immediate, high-impact actions such as energy efficiency improvements, packaging optimization, and supply chain enhancements—can drive meaningful reductions in environmental impact.

Beyond carbon metrics, sustainability requires a holistic strategy that incorporates ethical labor practices, responsible procurement, and corporate accountability. Rating systems like EcoVadis help ensure companies move beyond compliance, promoting transparency and continuous improvement.

Ultimately, the path to sustainability in the cleanroom industry is not about waiting for perfect solutions but about taking decisive action now. By embracing practical, science-based measures and prioritizing tangible improvements over theoretical benchmarks, companies can drive real progress toward a cleaner future.