The science of mopping

Consistent techniques for cleanroom cleaning and disinfection

By Stefaan Vanhalle – R&D Manager STAXS®

Maintaining regulatory compliance in cleanroom environments requires more than just the use of validated disinfectants and cleaning agents, it also demands the use of cleanroom-compatible tools, such as (sterile) mops, and a rigorous, repeatable technique that ensures uniform coverage and minimizes the risk of recontamination. Mopping, often seen as a basic task, becomes a critical component in contamination control when applied to GMP- or ISO-classified areas. Proper technique, especially when cleaning floors, walls, and ceilings, is essential for achieving consistent results in both cleaning and disinfection.

The base principles

Cleanroom mopping should always follow the principles of unidirectional mopping, controlled overlap (10-20%), and progressive movement from clean to dirty zones. Unidirectional wiping is critical because it ensures that contaminants are consistently pushed in a single direction, allowing them to accumulate at the leading edge of the mop. If the mop is moved back and forth, these collected particles risk being redistributed onto already cleaned surfaces, undermining the cleaning efficacy and increasing the risk of recontamination.

It is considered best practice in cleanroom environments to clean from top to bottom, following the principle of moving from clean to less clean areas. This means starting with the ceiling, then proceeding to the walls, and finishing with the floor. This sequence minimizes the risk of recontamination, as particles dislodged during ceiling or wall cleaning can settle downward. However, it is important to note that the cleaning and disinfection frequency for ceilings, walls, and floors is not uniform. In practice, floors are cleaned most frequently, while walls and ceilings are addressed less often, according to risk-based schedules.

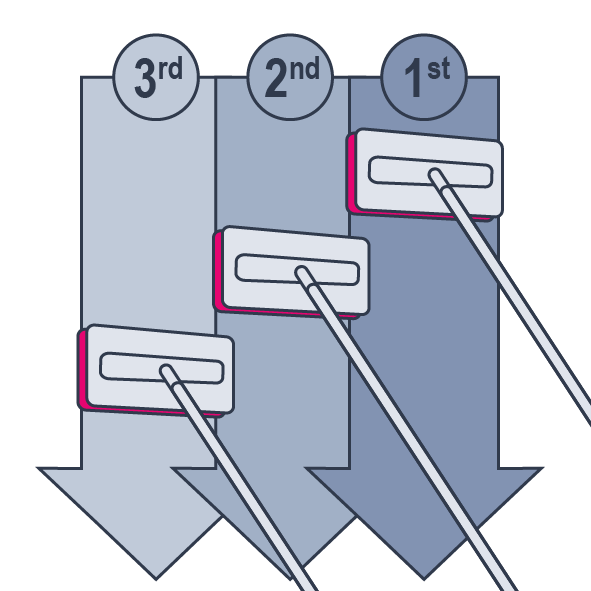

Ceilings

Cleaning ceilings presents a unique challenge due to their overhead orientation, height, and limited accessibility. To solve this, the pull-lift technique has proven to be an effective solution. This method involves the use of a telescopic handle equipped with a swivel head, which allows the operator to maintain control and precision while working above their head. The mop is drawn in straight lines toward the operator, allowing for consistent coverage across the ceiling surface. Each pass should overlap the previous one by 10–20%. This method ensures that contaminants are captured and lifted with minimal redistribution, while also being the most ergonomic choice for the cleaning of ceiling areas.

Walls

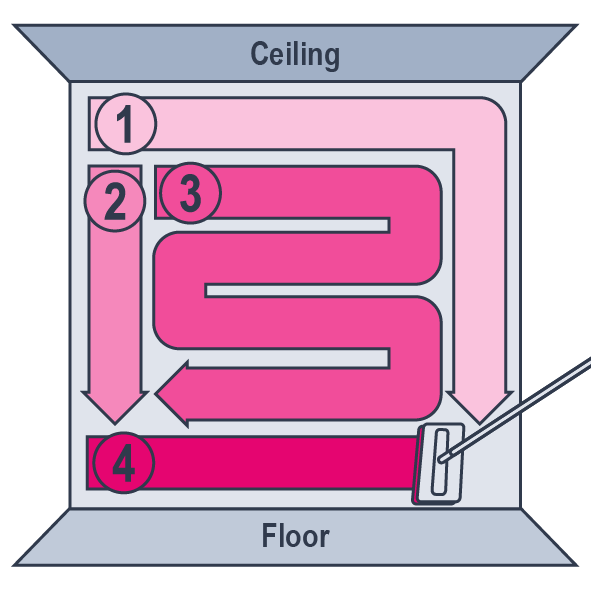

Walls are typically cleaned using the perimeter-then-S technique. The process begins in the upper-left corner of the wall, where the operator makes a horizontal stroke from left to right, along the top edge of the wall, just beneath the ceiling. Upon reaching the upper-right corner, the operator moves down with a vertical stroke, until one mop-width above the floor. Then they return to the left-side of the wall, and repeat the vertical motion just below the previous pass. As a result the operator has cleaned along the perimeters, from the top section of the wall down to a level approximately one mop-width above the floor. This precaution helps avoid dragging floor-level contamination upwards during the cleaning process. Once the perimeter strokes are complete, the operator proceeds with smooth, S-shaped strokes between the two vertical strokes made before, moving from the top of the wall downward in a systematic, overlapping way.

The mop should maintain consistent contact with the surface, and each stroke should overlap the previous (by approximately 10–20%) to avoid missed areas. When the operator reaches the bottom section of the wall, just above the floor, the final cleaning pass consists of a horizontal stroke from left to right, spanning the lower edge that was initially left untouched. This final pass removes any settled particles near the base while preserving the clean-to-dirty directionality of movement. The result is a fully decontaminated wall surface, cleaned in a structured and contamination-controlled manner.

When cleaning cleanroom walls, interruptions such as windows, outlets, and switches require special attention. These features should be cleaned separately (after the mopping has been finished) using wipes, small mop heads, or cleanroom swabs. The operator should clean these elements, ensuring corners and edges are thoroughly wiped.

Floors

For the floors, S-motion techniques are commonly employed. Several variations of this method exist, three of which will be explored in more detail in this document. Regardless of the chosen technique, it is essential that the operator follows proper movement discipline to maintain both cleanliness and safety. When mopping the floor, the operator should always walk behind the mop, ensuring they do not step on freshly cleaned or wet surfaces. This is essential not only to avoid recontamination but also for safety reasons, particularly to prevent slipping hazards. At all times, the operator must ensure they are standing on a dry section of the floor and maintain a clear, unobstructed path as they progress through the room.

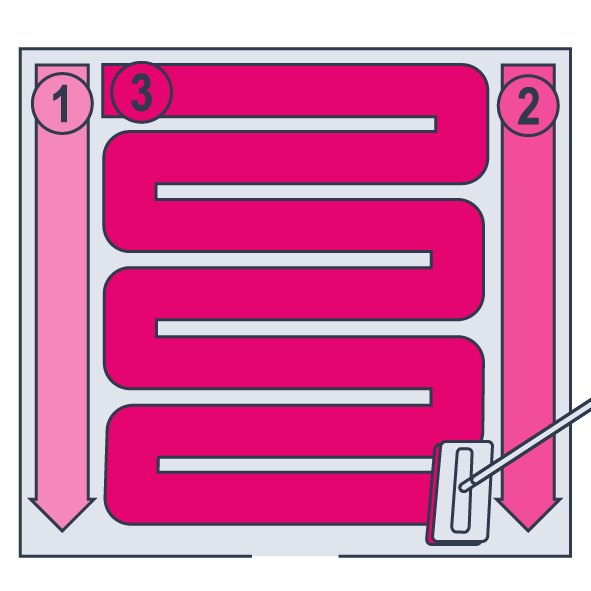

The first variant is the perimeter-then-S technique, executed with proper overlap and directional control. This method begins by mopping the perimeter of the area (typically along the edges of the room) to collect settled particles and prevent accumulation along borders. Once the edges are completed, the operator performs a continuous, sweeping S-shaped motion across the open central floor space, working systematically from the cleanest point (usually farthest from the exit) toward the exit door. The S-curves should be wide and fluid, with consistent overlap and control to prevent the re-deposition of contaminants.

The second variant is the Straight S-movement with fixed overlap. This approach involves a highly controlled S-pattern with a precisely measured linear overlap of 10–20% between strokes. The operator works in straight, parallel lines without crossing back over previously cleaned areas.

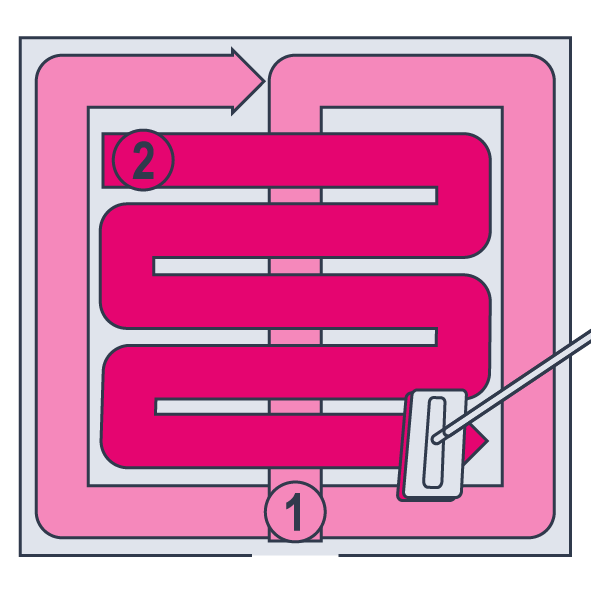

A third floor-mopping technique begins by drawing a straight central path through the middle of the room. Once the central line is complete, the operator turns and continues mopping along the perimeter wall, following the edges of the room in a clockwise or counterclockwise direction. This movement continues uninterrupted until the operator returns to the point where they first encountered the wall. This perimeter loop removes settled particles and prevents buildup in corners and edges. From there, the operator transitions to a standard S-shaped motion, working from the area nearest to the clean corridor toward the exit. As with other techniques, all strokes should maintain controlled overlap (typically 10–20%), consistent unidirectional motion, and progression from clean to less clean zones. This hybrid approach ensures both edge control and full-surface coverage.

Conclusion

To ensure these techniques are performed efficiently, cleanrooms should be kept as empty as possible during cleaning, with no unnecessary equipment or materials obstructing the floor area. The presence of obstacles requires a more tailored approach, often involving adjusted movements and localized detail cleaning. However, due to the highly situational nature of such adaptations, this white paper will not elaborate further on obstacle-specific strategies. The different techniques discussed in this white paper each have their own specific applications, advantages, and limitations, depending on factors such as room size, shape, obstacle layout, and accessibility. There is no such thing as a universally better or worse technique; the optimal choice depends entirely on the context in which it is applied.

Beyond technique, operator training is fundamental. Personnel must be taught not only how to clean, but why specific methods matter. Improper motions, such as circular wiping or using the same mop in multiple zones, can compromise entire cleanroom operations. Standard Operating Procedures should clearly define mopping procedures, and all activities must be recorded in real-time to ensure traceability.

Ultimately, effective cleanroom mopping is about control and consistency. With the right technique, the correct tools, and ongoing training, organizations can meet and exceed compliance standards protecting both their process integrity and the patients who rely on their products.

Your step-by-step decision checklist

Got all the mopping techniques down? Use this handy checklist to consider all options when it comes to mops, and find out what works best for your controlled environment!References

-

European Commission. (2022). EudraLex – Volume 4 – EU Guidelines for Good Manufacturing Practice for Medicinal Products for Human and Veterinary Use: Annex 1 Manufacture of Sterile Medicinal Products.

-

Harrison, R. (2019). Cleanroom Cleaning: Tools, Techniques, and Validation. VWR International White Paper.

-

United States Pharmacopeia. (2022). USP <1072> Disinfectants and Antiseptics. United States Pharmacopeial Convention.

-

Whyte, W. (2010). Cleanroom Design (2nd ed.). Wiley-Blackwell.

- ISO. (2015). ISO 14644-5: Cleanrooms and associated controlled environments – Part 5: Operations.